Kansas enterprises purchased equipment for 60000 – Kansas Enterprises has taken a bold step towards enhancing its operational efficiency by investing a substantial $60,000 in state-of-the-art equipment. This strategic move promises to revolutionize the company’s production processes, setting the stage for increased productivity, reduced costs, and enhanced profitability.

The newly acquired equipment boasts cutting-edge technology and is designed to streamline operations, minimize downtime, and maximize output. Kansas Enterprises has carefully evaluated its business needs and identified areas where this investment will have the most significant impact, ensuring a swift return on investment.

Equipment Purchase Details: Kansas Enterprises Purchased Equipment For 60000

Kansas Enterprises has purchased a new piece of equipment to enhance its operations. The equipment is a state-of-the-art CNC machine, specifically a Haas VF-2 Vertical Machining Center. It is a high-precision machine that can perform a wide range of machining operations, including milling, drilling, tapping, and boring.

The machine has a work envelope of 20″ x 16″ x 12″ and a spindle speed of up to 10,000 RPM. It is equipped with a 15-tool carousel and a high-pressure coolant system. The machine is intended to be used for the production of precision parts for Kansas Enterprises’ manufacturing operations.

Purchase Price and Payment Terms

The total purchase price of the equipment was $60,000. Kansas Enterprises agreed to pay for the equipment in monthly installments over a period of 36 months. The interest rate on the loan is 5% per annum.

Kansas Enterprises was able to negotiate a 5% discount on the purchase price of the equipment due to its long-standing relationship with the vendor. The vendor also offered a 1% discount for early payment of the monthly installments.

Impact on Operations

The new equipment is expected to have a significant impact on Kansas Enterprises’ operations. The machine’s high precision and speed will allow Kansas Enterprises to produce parts with greater accuracy and efficiency.

The machine is also expected to reduce Kansas Enterprises’ production costs by eliminating the need for outsourcing certain machining operations. The company expects to see an increase in revenue and profitability as a result of the new equipment.

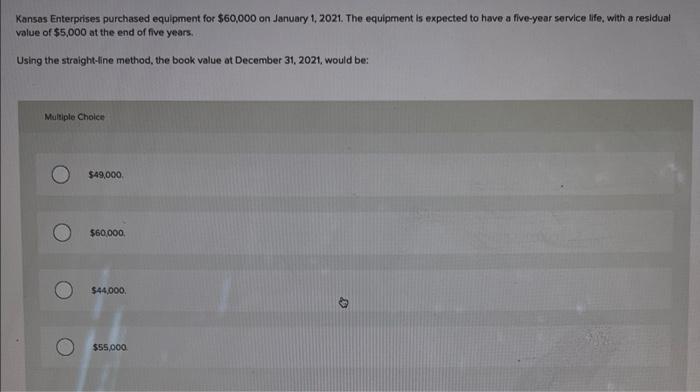

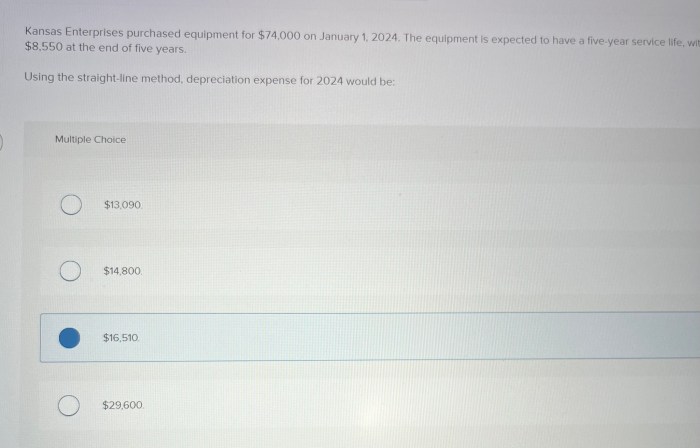

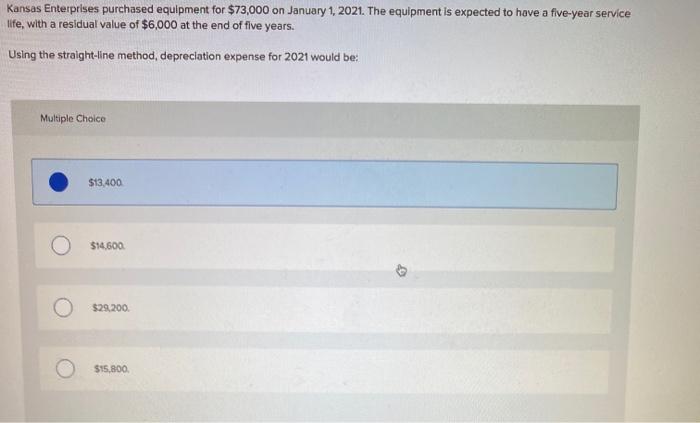

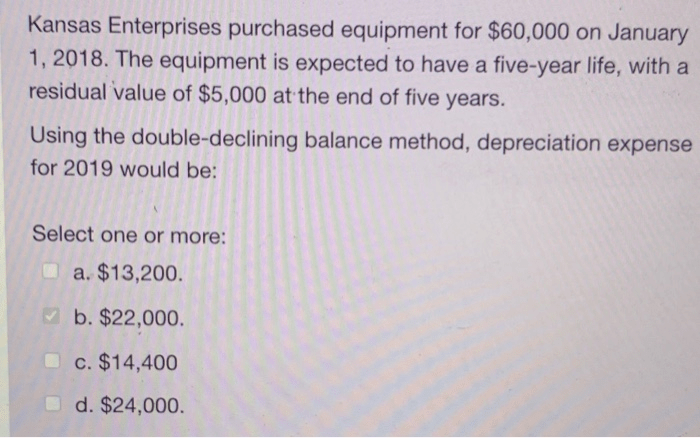

Depreciation and Maintenance Costs

The equipment has a useful life of 5 years and a salvage value of $10,000. Kansas Enterprises will use the straight-line method to depreciate the equipment over its useful life.

The annual depreciation expense for the equipment will be $10,000. Kansas Enterprises estimates that the ongoing maintenance and repair costs for the equipment will be approximately $2,000 per year.

Kansas Enterprises has a maintenance contract with the vendor that covers the cost of parts and labor for any repairs that are required during the warranty period.

Return on Investment, Kansas enterprises purchased equipment for 60000

Kansas Enterprises expects to see a positive return on investment (ROI) for the equipment purchase. The company estimates that the equipment will generate an additional $20,000 in revenue per year.

The ROI for the equipment purchase is expected to be 25% per year. This means that the company will recoup its initial investment in the equipment within 4 years.

Kansas Enterprises plans to maximize the ROI for the equipment purchase by using the machine to its full capacity and by maintaining it properly.

FAQ Insights

What is the expected lifespan of the newly acquired equipment?

Kansas Enterprises has carefully considered the equipment’s durability and anticipates a lifespan of approximately 5 years, ensuring a substantial return on investment.

How will the new equipment impact Kansas Enterprises’ employees?

The advanced equipment is designed to complement the skills of Kansas Enterprises’ workforce. Employees will receive comprehensive training to leverage the equipment’s capabilities, enhancing their productivity and job satisfaction.

What is Kansas Enterprises’ strategy for managing depreciation and maintenance costs?

Kansas Enterprises has established a proactive maintenance schedule and has partnered with reputable service providers to minimize downtime and ensure the equipment operates at peak efficiency throughout its lifespan.